The Scaleman Company Is Your Full Service Scale Experts

Scales can become out of calibration for a variety of reasons including wear and tear on components, environmental changes, buildup under the scale and more.

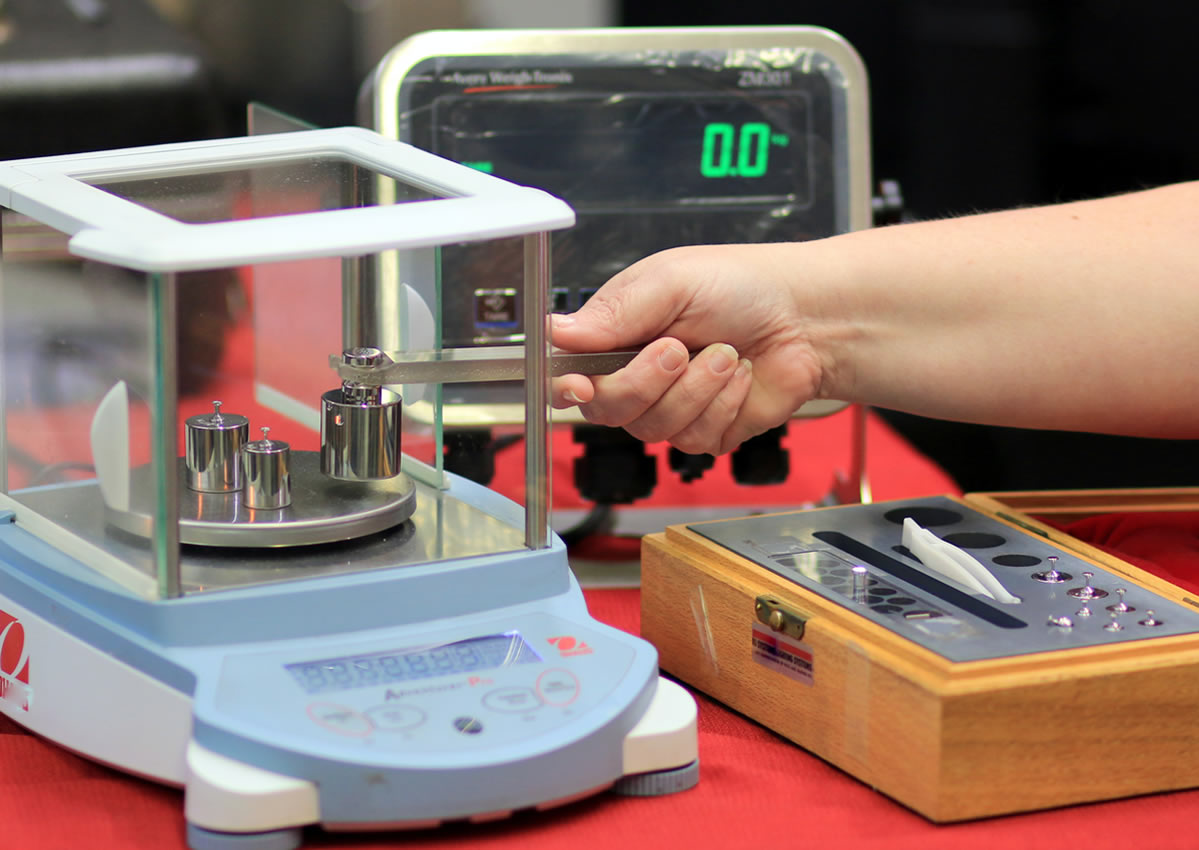

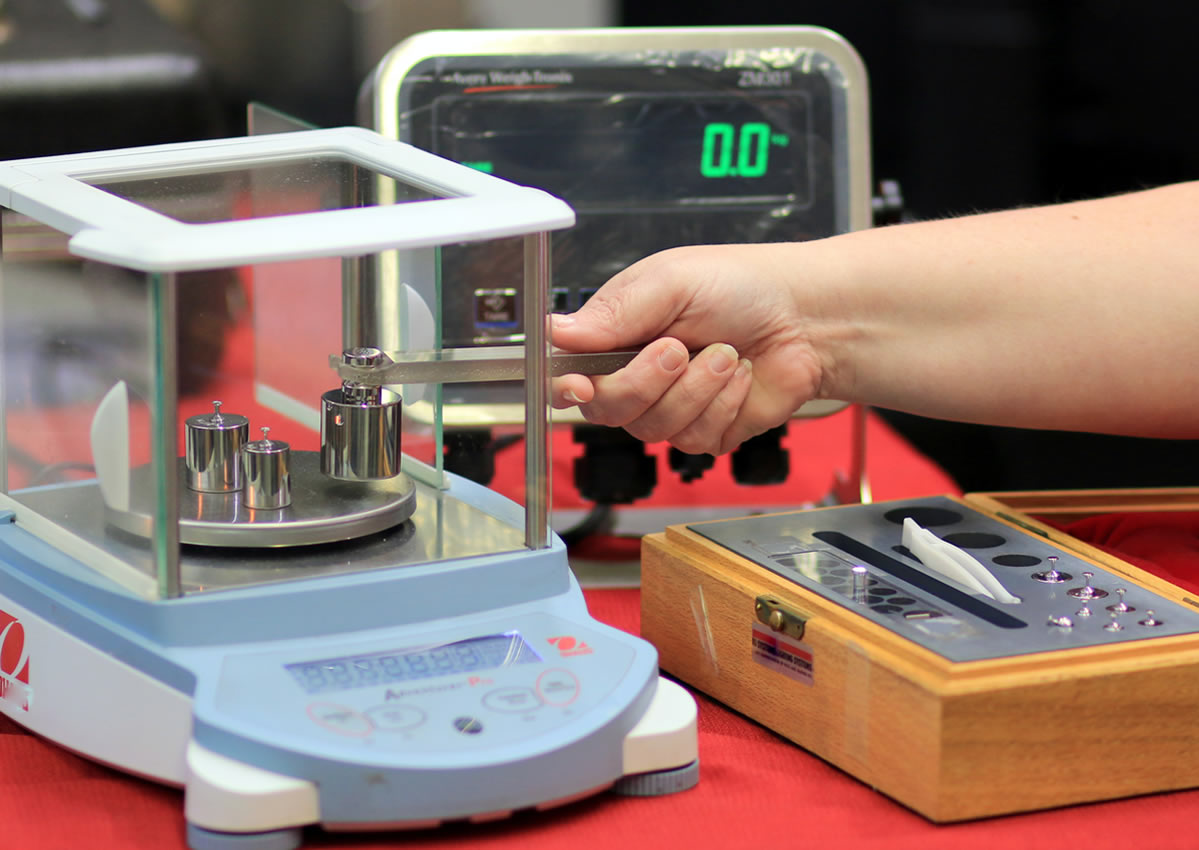

The problem with a scale out of calibration is someone always loses. In commercial transactions, either the seller is giving away free product or the buyer is paying for product he or she did not receive. Scale calibration is one of the core services provided by The Scaleman Company. Our technicians can calibrate any manufacturer or capacity of electronic or mechanical scale. Our technicians use certified known weights, traceable to NIST to calibrate. After weight testing and calibration, we create Certificates of Calibration. We can customize calibration certificates to meet your business needs. Contact our service department for more information or a sample of our Certificates of Calibration.

Preventative Maintenance

Many times a scale is a business’s cash register; inaccurate weight readings and unexpected down time can lead to lost revenue. One way to minimize these issues is to routinely perform preventative maintenance on your scale. Below is the list of tests and inspections done during a Standard Preventative Maintenance appointment. A regularly scheduled preventative maintenance service will extend the life of your scale, maintain accuracy, avoid equipment downtime and minimize repair expenses.The Scaleman Company’s technicians can customize a preventative maintenance service designed specifically for your scale. Call our service department for an appointment or more information.

Standard Preventative Maintenance

- Test indicators and load cells

- Inspect and clear the area surrounding the scale

- Level and examine condition of the platform

- Test moisture levels in boxes, cables, and load cells

- Inspect cables for damage

- Inspect and test connections

- Test using weight standards traceable to NIST

- Adjust and calibrate per guidelines specified in Handbook 44

- Generate Certificates of Calibration

Repairs

The Scaleman Company’s technicians pride themselves in troubleshooting inaccurate and malfunctioning scales. Our techs work to restore the integrity of your equipment as efficiently and cost effectively as possible. In most cases, we can make the repairs during the same day because our utility and test trucks arrive stocked with tools, parts, and NIST traceable certified test weights.

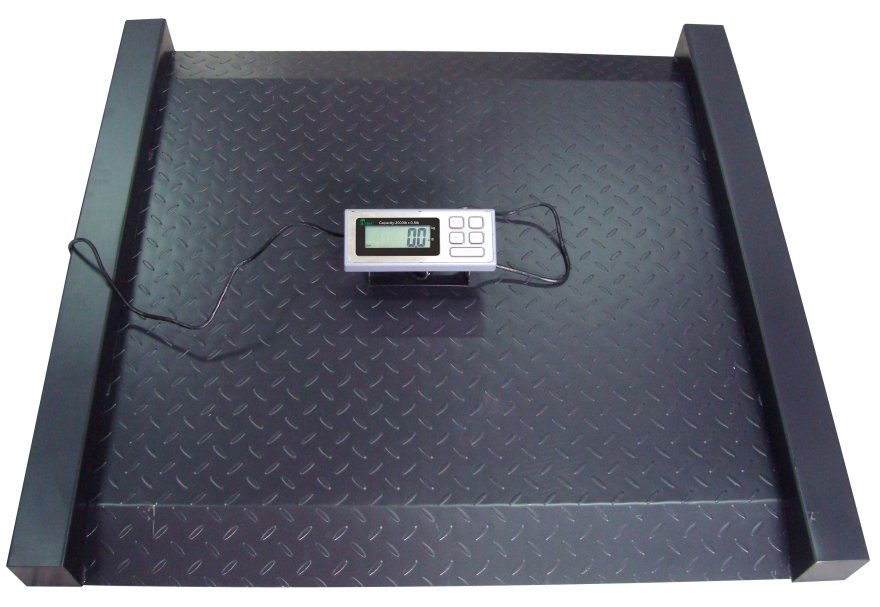

Installations

The Scaleman Company’s technicians have the skills to install any manufacturer, model, or capacity of electronic and mechanical scales. After any installation, we calibrate the scale using NIST certified traceable weights and place the equipment into service with Weights and Measures if required. Think of The Scaleman Company as your turn-key solution to scale installation.

Conversions

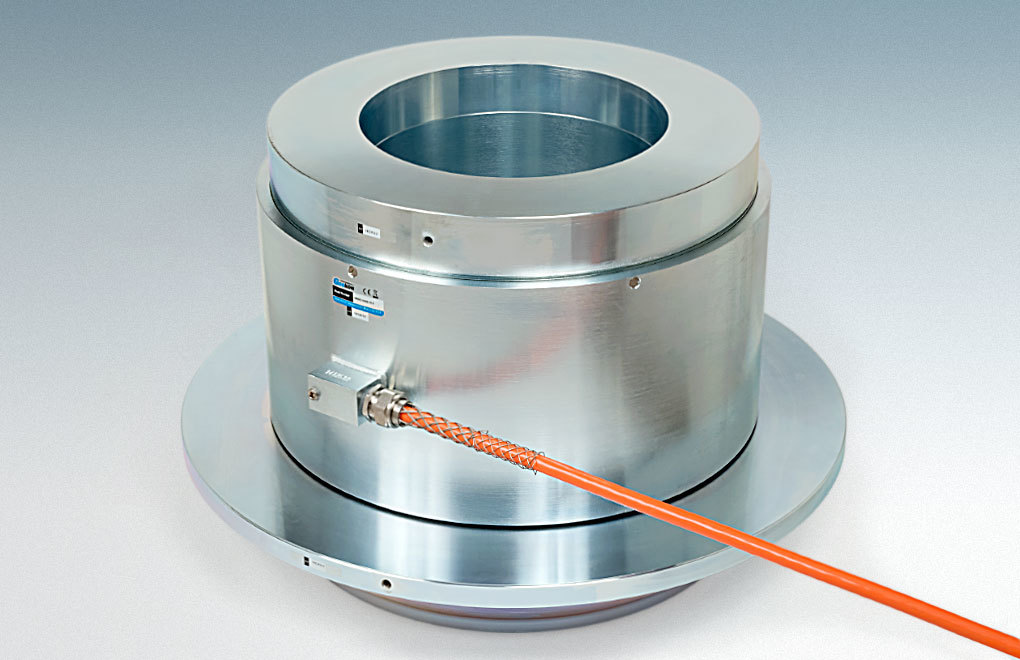

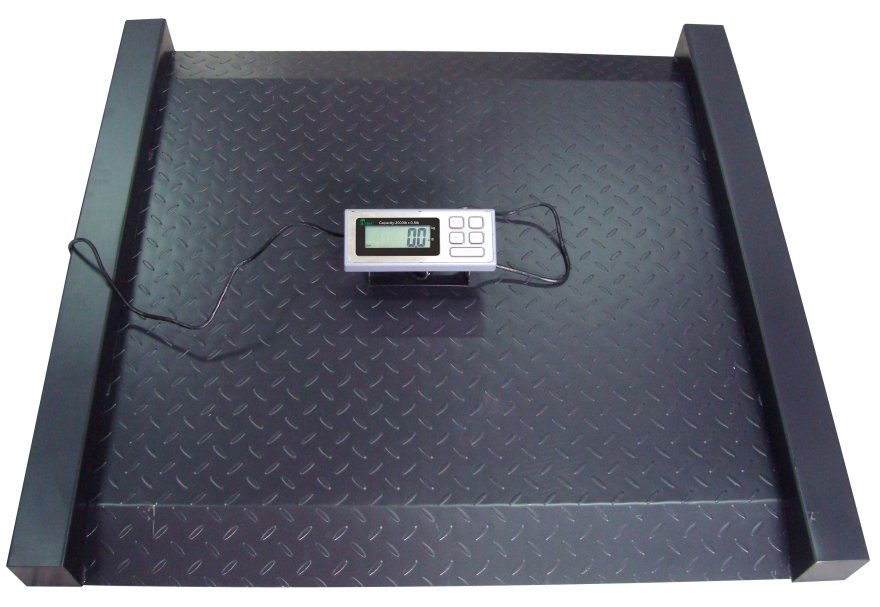

Electronic scales now dominate the scale market and are driving mechanical scales and parts towards obsolescence. If you own a mechanical scale, you know replacing worn out or damaged parts can be pricey or even impossible to source. One way to solve this problem is to convert your mechanical scale to electronic using load cells. Mechanical conversions begin with replacing a scale’s mechanical “weighing beam” with a load cell. Load cells installed within the mechanical system give the scale an electrical weight reading by measuring the load applied to the scale. The load cell’s electrical weight reading allows for data collection and printing, eliminating human error from hand written tickets. Mechanical conversions can be performed on almost all mechanical truck scales, hoppers and floor scales. The Scaleman Company has completed conversions for satisfied customers who report ease of use, greater accuracy as well as fewer costly repairs after their scale conversion. Out with the old weight, in with the new!

Need scale repair service ASAP? Our technicians are available 24/7/365 for emergency service. The Scaleman Company knows scales can malfunction any hour or day of the week. Visit Our Contact Page https://thescalemancom.wpengine.com/contact-us/ Or Call 631-957-2272 For Estimate Today.

Why scale maintenance is important and will save you money in the long run

When you are dealing with industrial scales, you have to expect them to need scale repair services or calibration often. Due to the workload, these scales can very easily cost you thousands to purchase new, so maintaining and servicing your equipment is crucial to the longevity of your scales. While scales can get damaged for numerous reasons one of the most common is improper maintenance and care. When a scale does become damaged you need to make sure you use get scale repair services from a certified facility. Industrial scales have very specific calibrations that must be adjusted right, unique parts and cannot be repaired by a general electronics technician. In order to make sure your scales are serviced properly you should follow our basic guidelines to know quality scale repair and how to get it.

Calibration Is Key

Scales are imperative because they provide exact measurements for many industrial purposes. Accuracy is the top priority as many factors depend on it such as compliance with ISO standards, regulatory bodies and load limits. When seeking scale repair services it is important to ask questions about their calibration service and methods. You want to make sure they are qualified to calibrate to dead on accuracy.

Scale Repair Services You Can Count On

You should also ask as many questions as you have before having scale repair performed about your equipment. Questions like what replacement parts will be used, will they be new or remanufactured. What is the warranty on the labor and parts for the repair? You are going to be counting on this business to give your scales back to you in new working order; so asking these questions up front will make sure you are on the same page. If the repairs are not done right it can affect the mechanical validity of your scale, the accuracy or it could fail altogether. Accuracy and downtime are two factors that can sideline your entire business. So you want to make sure their technicians are certified and experienced and that you can count on them as you do your scales.

Is The Repair Guaranteed?

Make sure when looking over the repair or service agreement that you pay special attention to the warranty of their work and parts. Many companies can confuse you with hidden exclusions and voidable clauses. So when it comes to spending hundreds or more on a repair you are going to want some kind of guarantee on paper that explains your rights and any limitations clearly.

Need Scale Repair From The Best?

If you want scale repair from one of the most respected names in the business, you should contact The Scaleman Company. We handle industrial scales geared towards any application and we have been around for over 50 years servicing the industry. We stand behind our work and our word to give you the best in scale repair services at a fair price. Contact us today for a consultation and see the difference in your equipment when maintained by The Scaleman Company. Call us today 631-957-2272.

Different Types of Load Cells

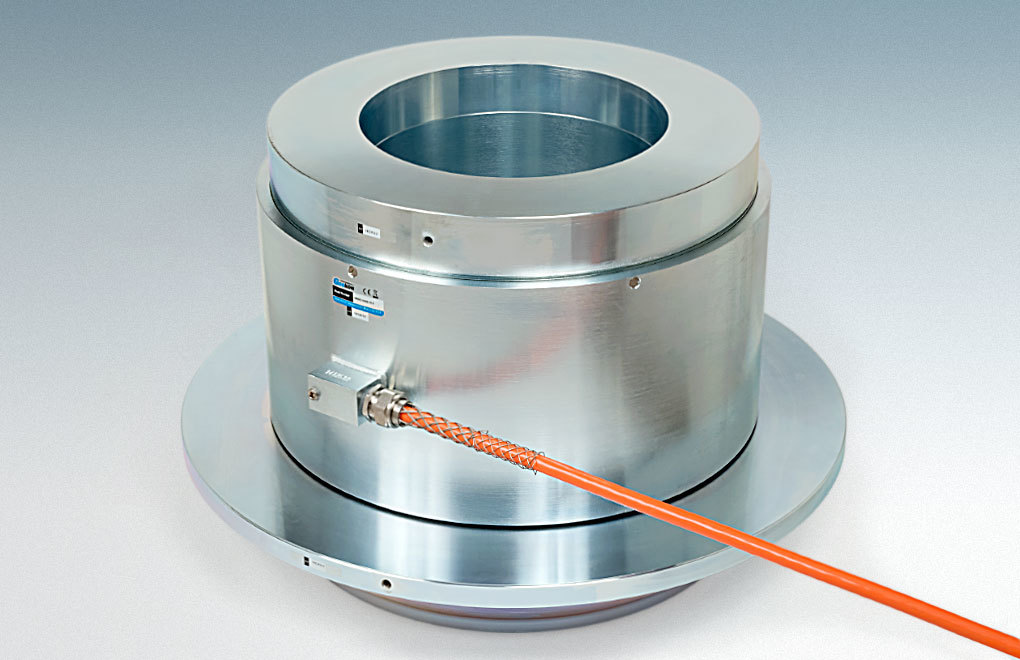

If you work or have worked in an industry that involves regular weighing of your products or goods, you have probably heard of the term load cell. While you know they must be working correctly in order to have your digital scales functioning properly, most people do not fully understand what they are and the different types of load cells. In order to better understand the importance of a load cell, you must first learn what exactly a load cell is.

A load cell is a transducer that is used to create an electrical signal whose magnitude is directly proportional to the force being measured. Specific to weight and scales, a load cell is a weight measurement device necessary for electronic scales that display weights in digits. Basically, this is the component of the scale which allows you see the weight, in the proper numerical digits, of whatever you are weighing. Seems pretty straightforward and self explanatory. However, there are three different types of load cells; low capacity, mid-range and high capacity, which each function to meet the demands required by various industries. Please click the link below to learn more about the different types of load cells and which would meet your industry’s needs.

https://www.800loadcel.com/load-cell-types.html

Credit Load Cell Central

How do I Fix a Digital Scale?

Most people own one or more digital scales in their home or business. While they make weighing items or equipment much easier, they do tend to not work properly from time to time. The questions is, when this happens, what can you do to fix the digital scale? There are some quick troubleshooting steps to consider when examining your digital scale.

First and foremost, you want to make sure the scale is placed on a flat and level surface. Uneven surfaces such as carpets or inclines may produce inaccurate readings. If the measurements seem unusual, check the LCD screen for proper connection. Should you still have an issue, make sure to check the batteries and make sure they are not fully drained. Of course, if you are dealing with heavy duty industrial scales, and the issue persists, make sure to contact a company with trained service technicians to do a proper inspection of your equipment.

For more information, please visit the link below:

https://www.reference.com/home-garden/fix-digital-scale-7d5def705e708d86

*Credit Reference.com*

The Importance of Using Thermal Printing Paper

Thermal printing paper is a specialty paper that provides “inkless” printing, resulting in the clearest, most crisp high definition images possible. The healthcare and retail industries along with ticketing agencies all rely on thermal printing for the various benefits, specific to each industry.

Generally speaking, thermal paper printers are much faster, create higher quality images, are more durable and produce more lasting output, compared to other types of printers. These factors will allow for a smoother printing process for your business, cutting down time on having to wait or reprint documents and receipts, allowing your business to run faster and more efficiently.

For more information on why it is important to use thermal printing paper, please visit the link below:

https://www.thermalpaperfacts.org/about

Credit Thermal Paper Facts Org

Proper Truck Scale Calibration Can Save You Thousands of Dollars!

Over time, a scale’s accuracy can degrade due to wear and tear. Accuracy is essential to your company because the value of the product you are transporting is determined based on weight. It’s also necessary to determine if your load weights are in compliance with federal safety regulations.

In a business where you are moving tens of thousands of pounds, a slight inaccuracy might seem negligible. The truth is that slight inaccuracies can accumulate to hefty costs for your business over time. Make sure you take the proper steps to ensure you are calibrated. Continue reading to learn more about proper scale calibration.

https://www.iscscale.com/blog/truck-scale-calibration/

Credit Industrial Scale Company